Contact Supplier

Mr. Kedan

Leave a message| Payment Type: | L/C,T/T,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,EXW |

| Min. Order: | 1 Piece/Pieces |

Basic Info

Model No.: SJW

Brand: XINDA

Raw Material: PP

Screw: Single-Screw

Inverter: Inverter

Electromagnetic Heater: Electromagnetic Heater

Automation: Automatic

Computerized: Computerized

Customized: Customized

Certification: SGS

Condition: New

Motor: Siemens Brand

Key Selling Points: Automatic

Output (kg/h):: 5-1800kg/h

Screw Type: Double Screw

Processing Type: Compouding/extruder/pelletizing

Used For: Pelletizing Granules

Voltage: 220V~340V

Motor Power: 200-250kw

Screw&barrel: Co-rotating,double Screw,clamshell

Application:: Color Masterbatch,Hot-melt Adhesive,ect

Additional Info

Packaging: Wood Box and Pallet

Productivity: 5-1800KG/H

Transportation: Ocean

Place of Origin: Jiangsu,China

Supply Ability: 1000

Certificate: ISO9001,CE,SGS

HS Code: 84772010

Port: SHANGHAI,QINGDAO,NINGBO

Payment Type: L/C,T/T,Money Gram,Western Union

Incoterm: FOB,EXW

Product Description

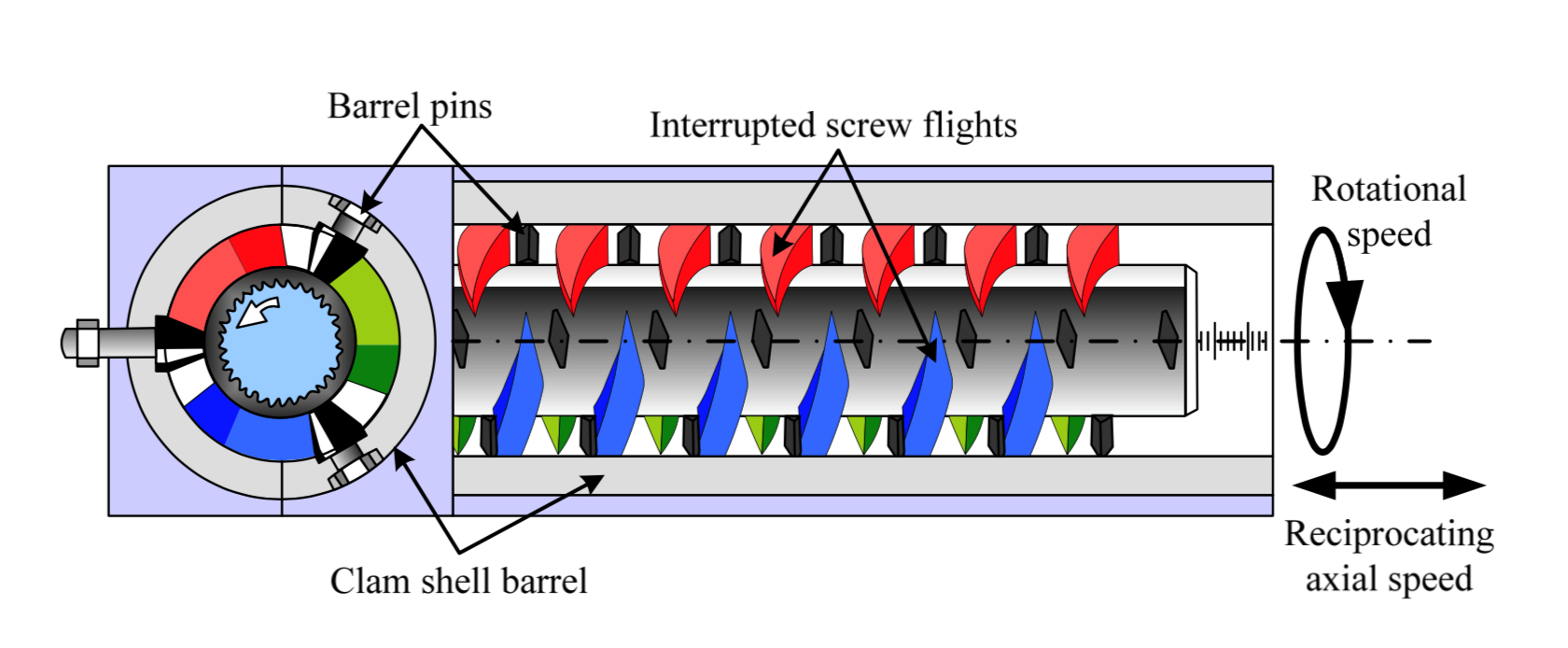

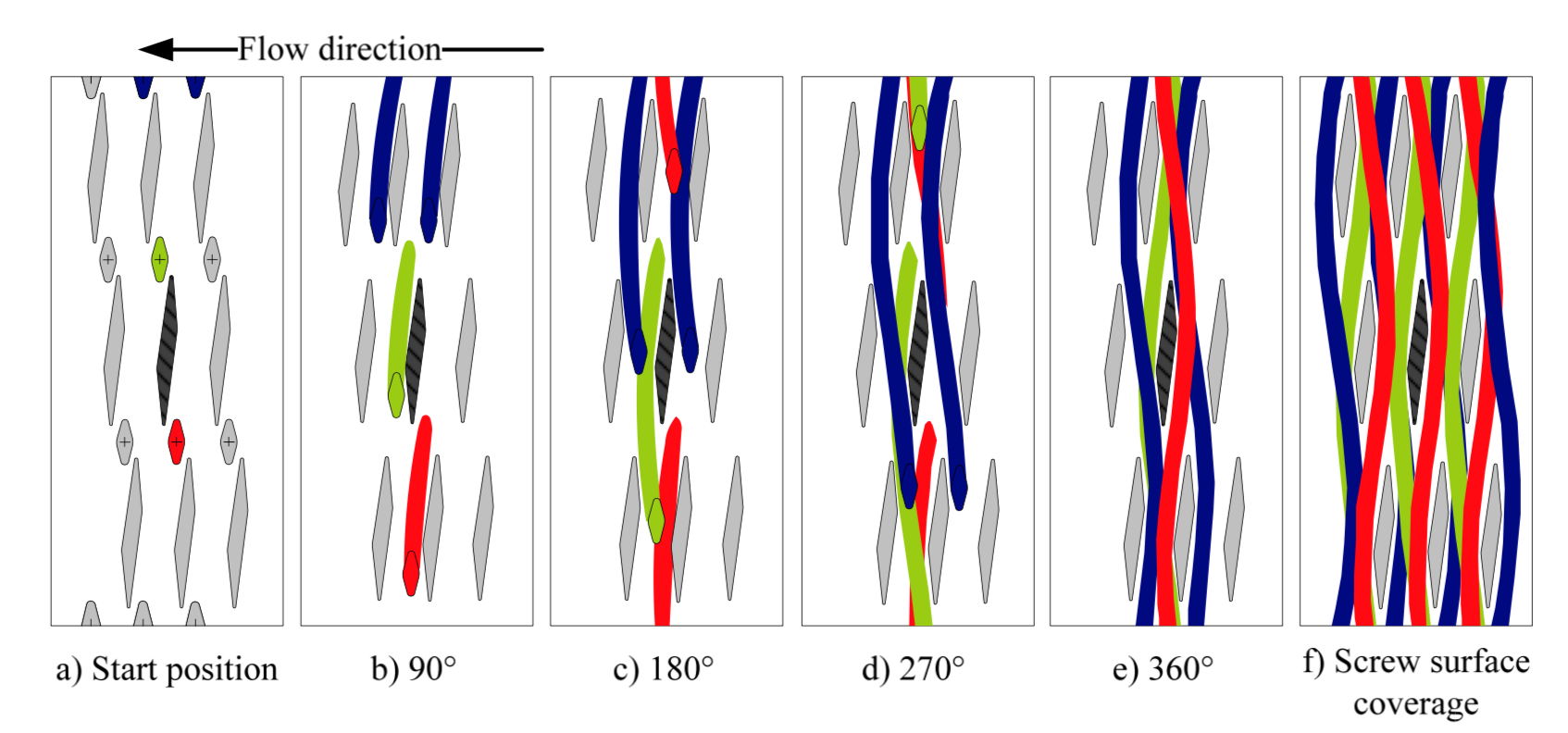

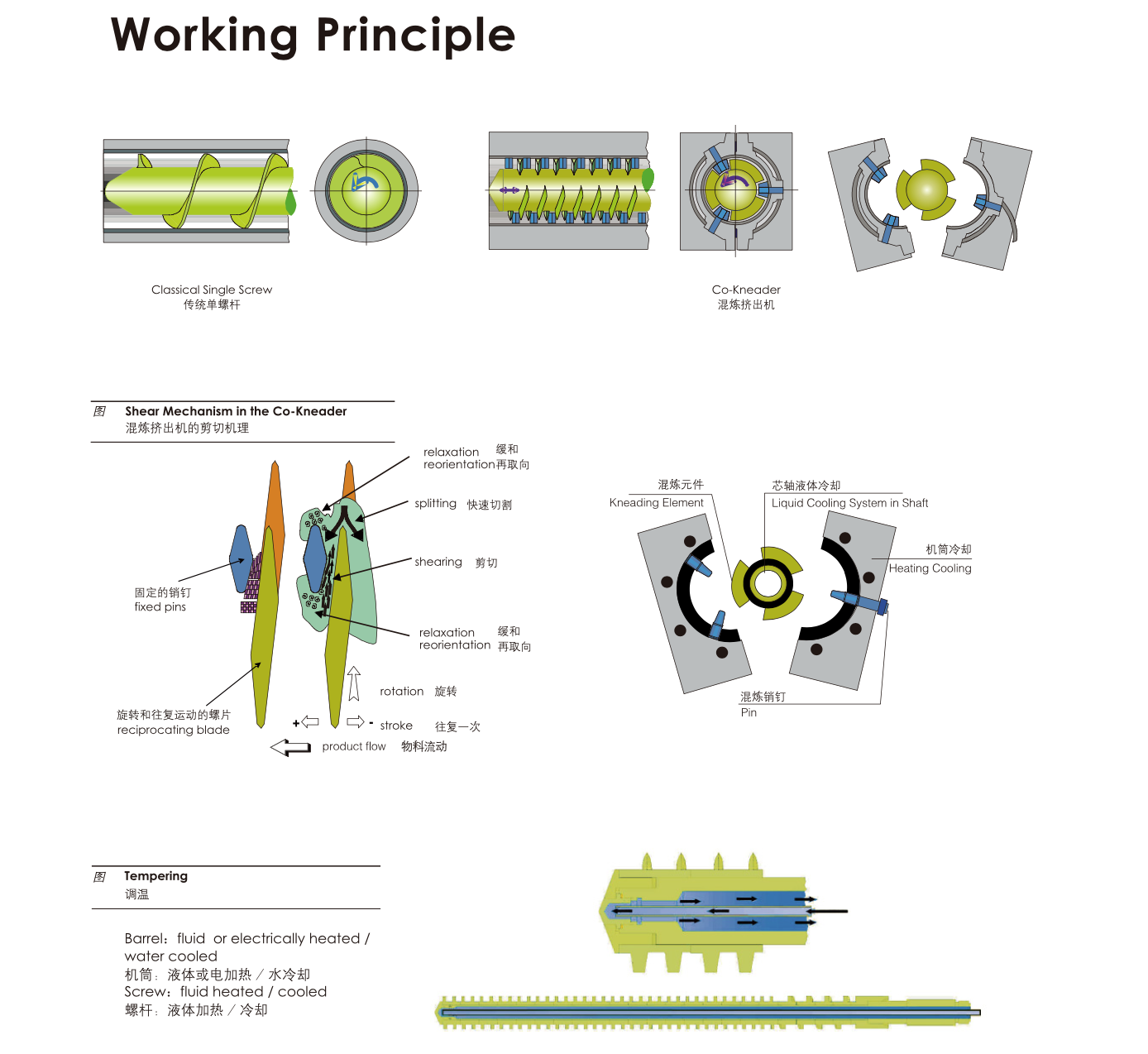

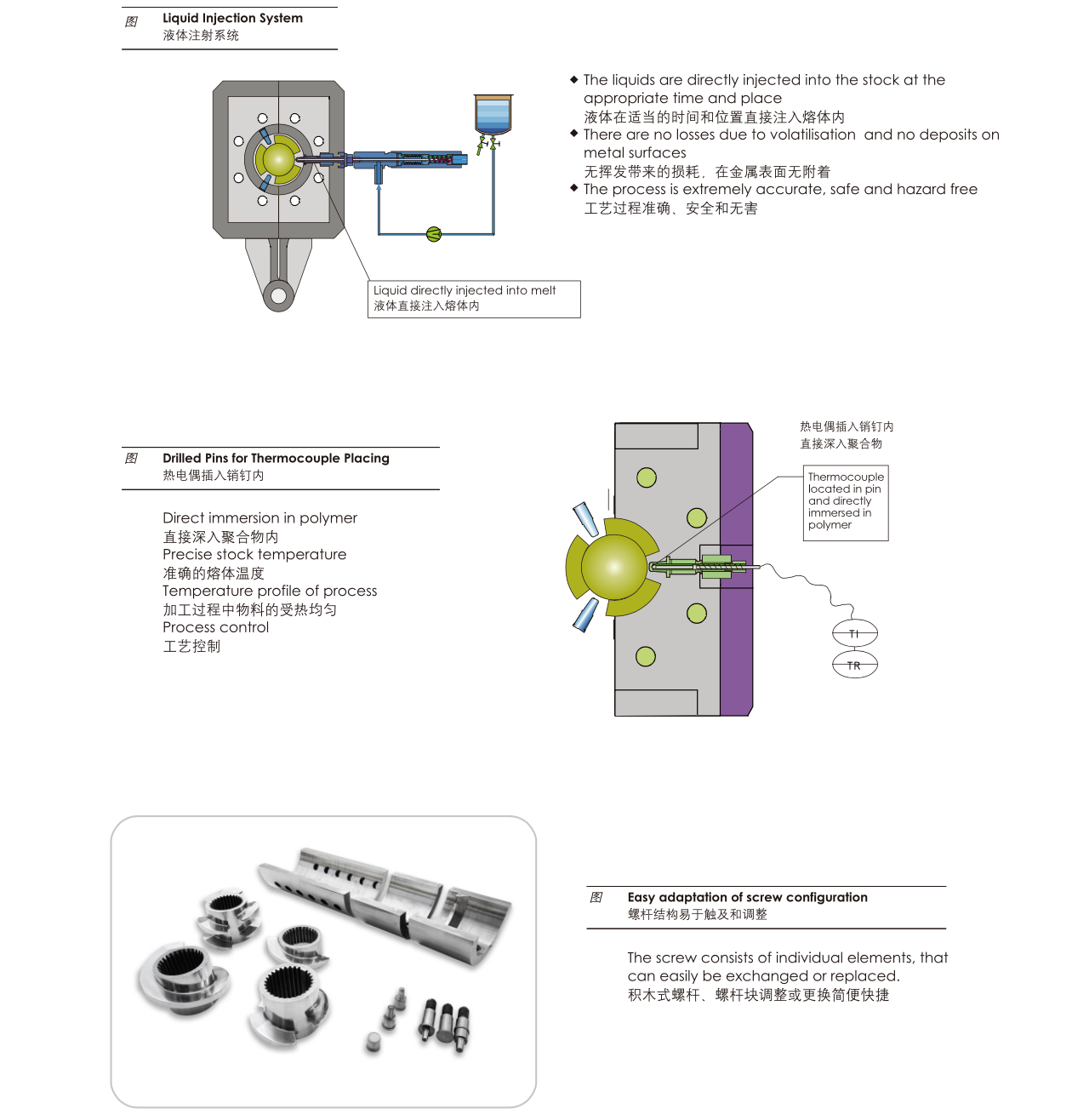

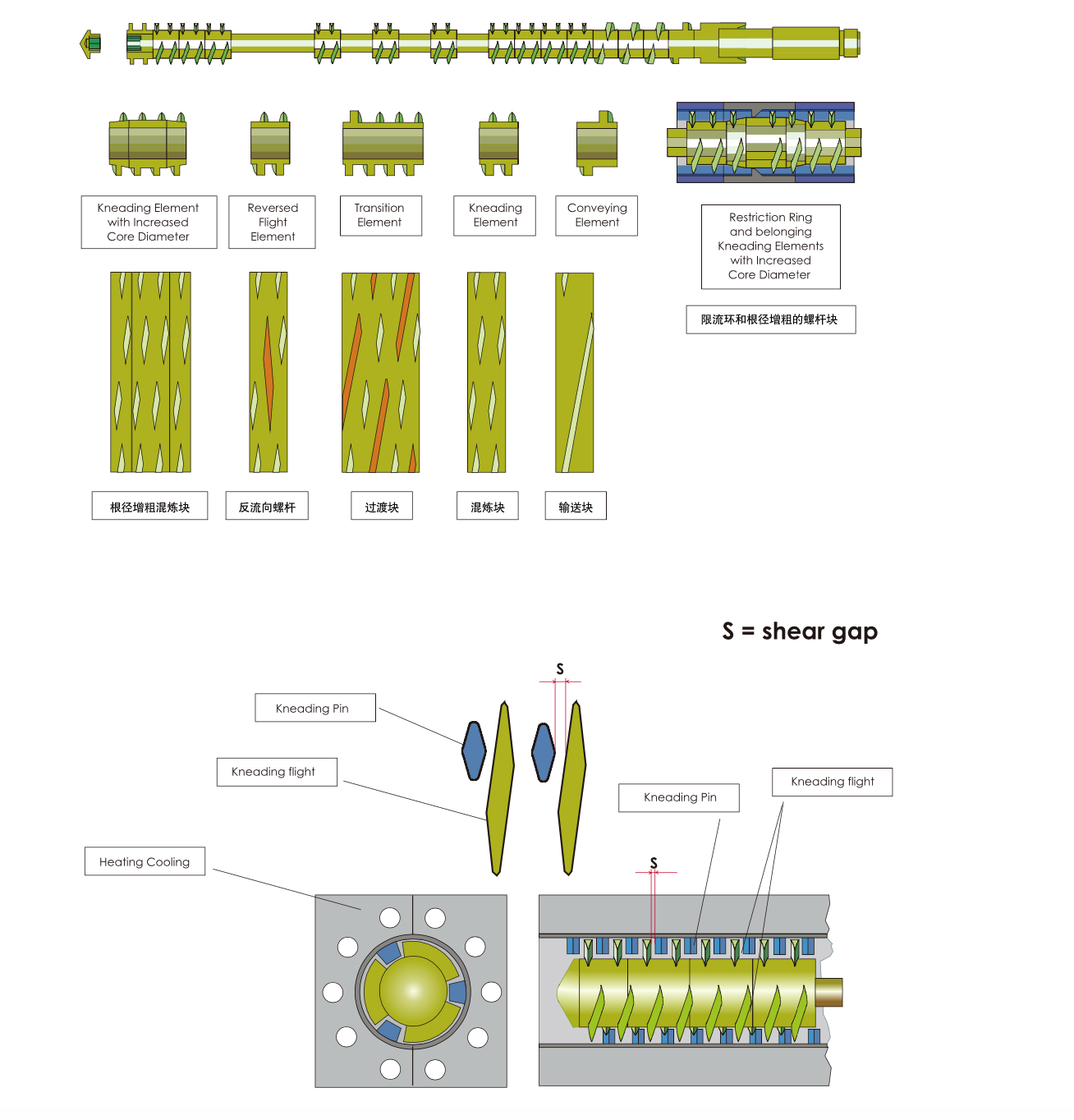

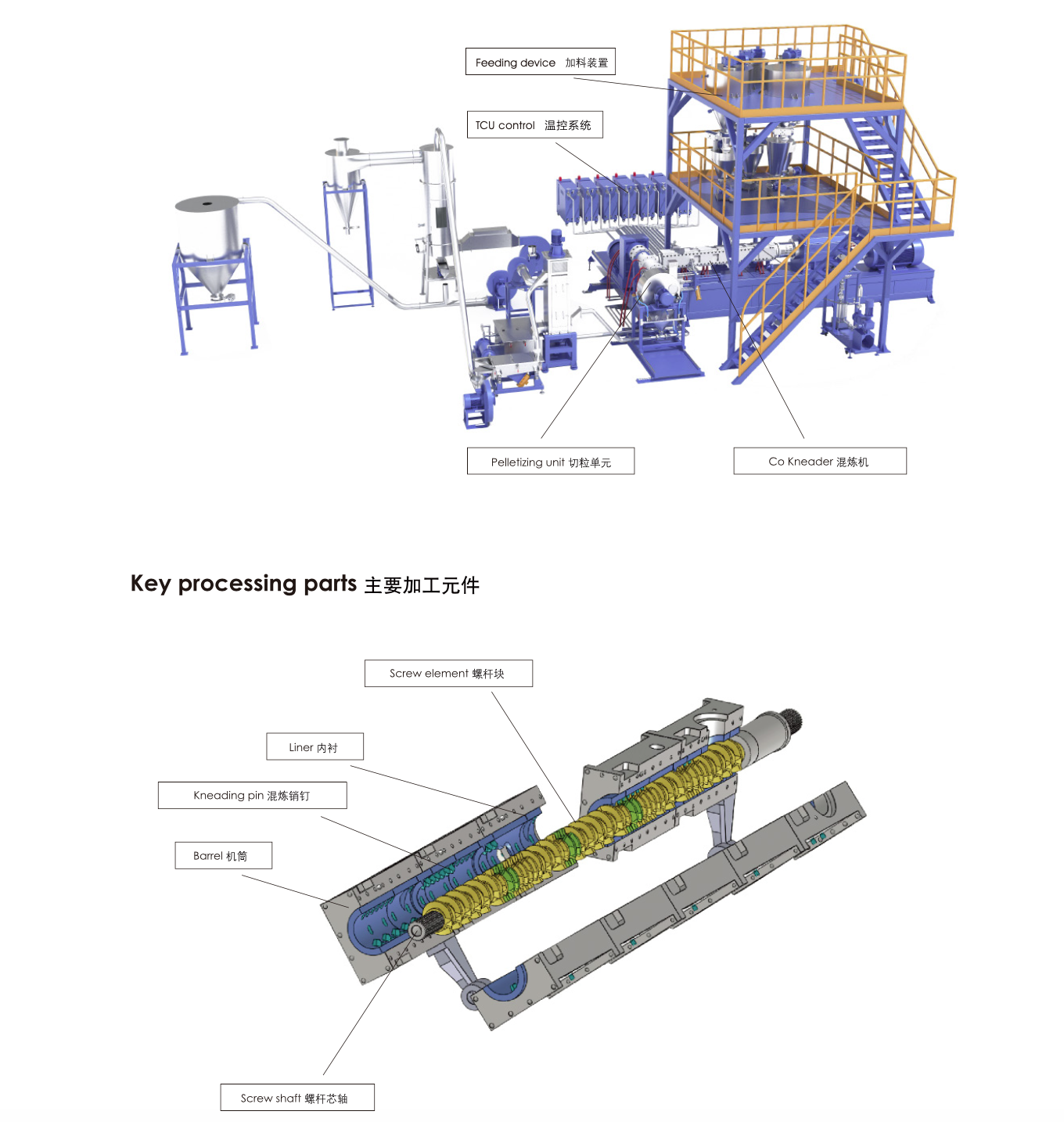

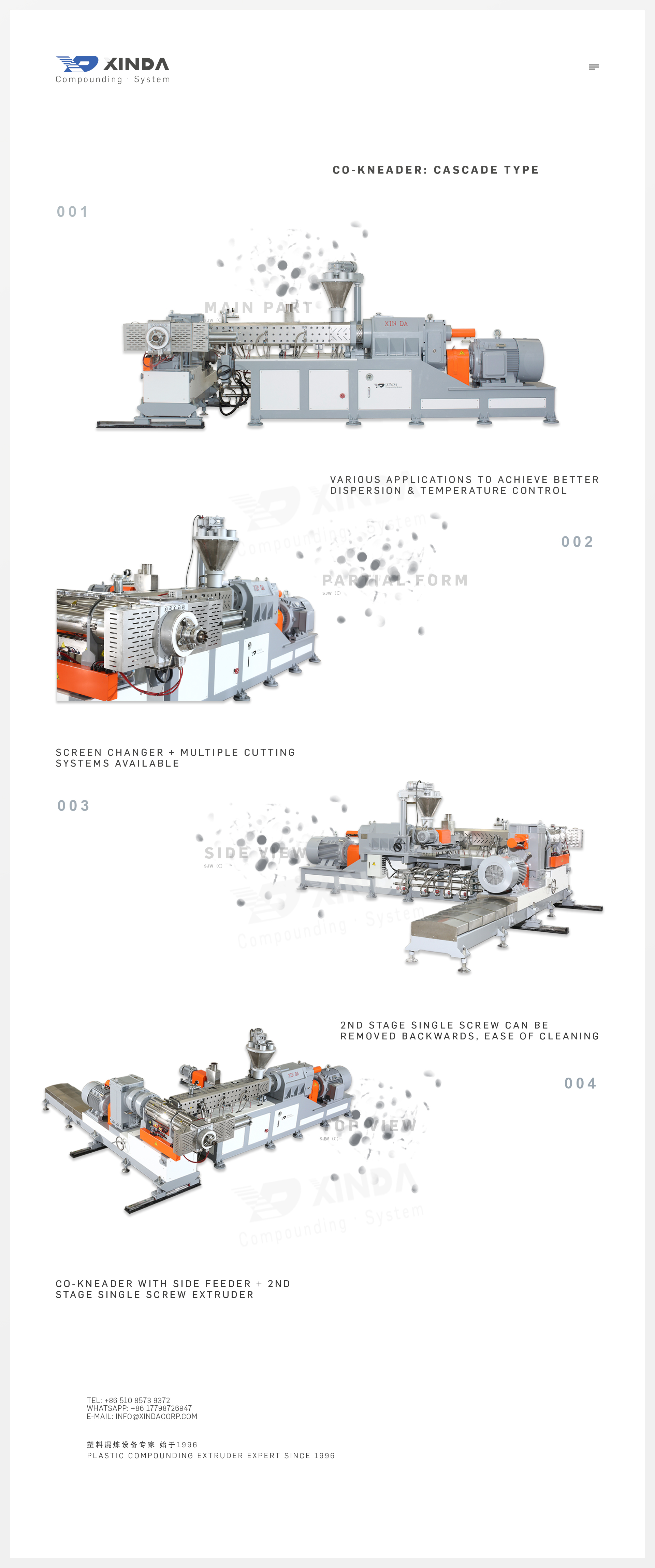

The Degradable Masterbatch Kneading and Compounding Extruder of Co-kneader reciprocating kneader consists essentially of the following assemblies: gearbox, oscillating equipment, vertical feeder, side feeder, screw, barrel, temperature control system, lubricant system. Working Principle

The Degradable Masterbatch Kneading and Compounding Extruder of Co-kneader reciprocating kneader consists essentially of the following assemblies: gearbox, oscillating equipment, vertical feeder, side feeder, screw, barrel, temperature control system, lubricant system. Working Principle

Strength for Co-kneader

Strength for Co-kneader

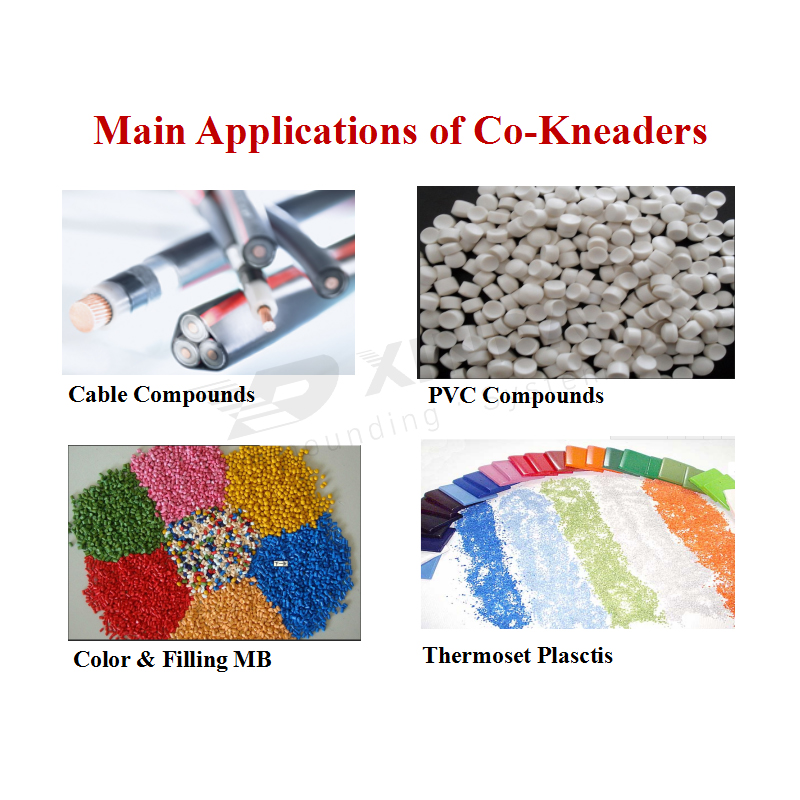

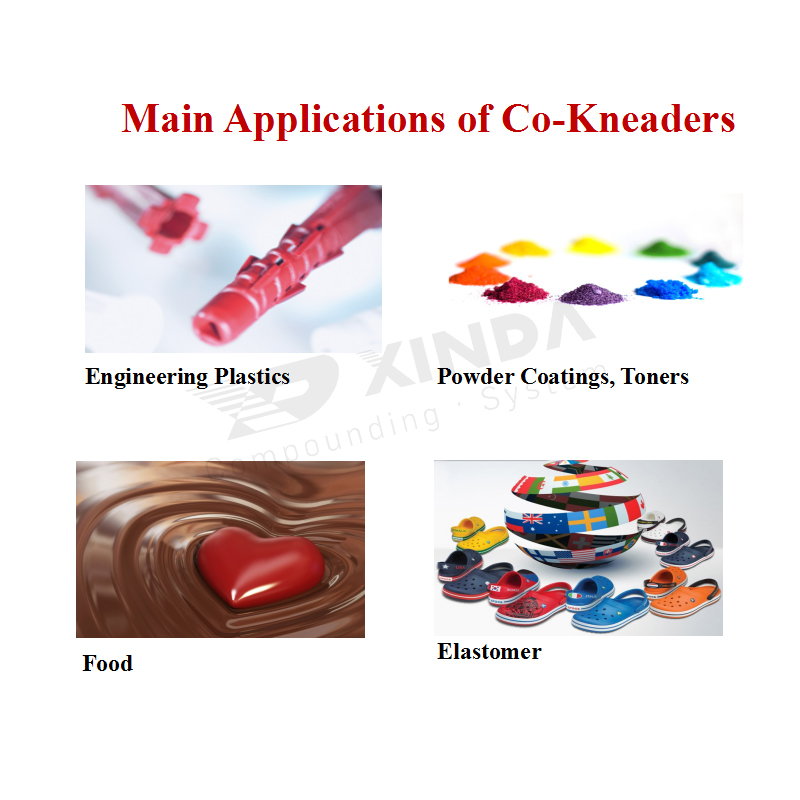

Model Reference (1)SJW(M)--Melt pump is installed between the main extruder and the die. The benefits of melt pumps for extrusion operations include the elimination of surging and other fluctuations, reduction of inconsistent melt temperatures, high pressures at lower product temperatures, compensation for the pumping or mixing capacity of the extruder, possibly reduced start-up times, and reduction of energy required by the extruder Application: --Color masterbatch/ Concentrates --High loading filler masterbatch --Hot-melt adhesive --Engineering plastics compounding --Engineered elastomers

Model Reference (1)SJW(M)--Melt pump is installed between the main extruder and the die. The benefits of melt pumps for extrusion operations include the elimination of surging and other fluctuations, reduction of inconsistent melt temperatures, high pressures at lower product temperatures, compensation for the pumping or mixing capacity of the extruder, possibly reduced start-up times, and reduction of energy required by the extruder Application: --Color masterbatch/ Concentrates --High loading filler masterbatch --Hot-melt adhesive --Engineering plastics compounding --Engineered elastomers | Model | SJW-45(M) | SJW-70(M) | SJW-100(M) | SJW-140(M) |

|---|---|---|---|---|

| Screw Diameter (MM) | 45 | 70 | 100 | 140 |

| Length Diameter Ratio | 15-25 | 15-25 | 15-25 | 15-25 |

| Main Motor Power (KW) | 15-30 | 55-75 | 90-132 | 160-220 |

| Max. Screw Speed (RPM) | 500 | 500 | 500 | 500 |

| Reference Output (KG/HOUR) | 40-50 | 150-200 | 300-400 | 800-1000 |

| Model | SJW-45(C) | SJW-70(C) | SJW-100(C) | SJW-140(C) | SJW-200(C) |

|---|---|---|---|---|---|

| Screw Diameter (MM) | 45 | 70 | 100 | 140 | 200 |

| Length Diameter Ratio | 20~25 | 20~25 | 20~25 | 20~25 | 20~25 |

| Main Motor Power (KW) | 15~30 | 55~75 | 90~132 | 160~300 | 350~550 |

| Second-stage Screw Diameter (MM) | 60 | 120 | 150 | 200 | 280 |

| Second-stage L/D | 7~8 | 7~8 | 7~8 | 7~8 | 7~8 |

| Second-stage Power (KW) | 15~22 | 37~45 | 55~75 | 90~110 | 132~160 |

| Max. Screw Speed (RPM) | 500 | 500 | 500 | 500 | 500 |

| Reference Output (KG/HOUR) | 40~70 | 150~250 | 300~500 | 800~1200 | 1900~3600 |

| Model | SJW-45(T) | SJW-70(T) | SJW-100(T) | SJW-140(T) | SJW-200(T) |

|---|---|---|---|---|---|

| Screw Diameter (MM) | 45 | 70 | 100 | 140 | 200 |

| Length Diameter Ratio | 7-15 | 7-15 | 7-15 | 7-15 | 7-15 |

| Main Motor Power (KW) | 15-30 | 55-75 | 90-132 | 160-220 | 350-450 |

| Max. Screw Speed (RPM) | 500 | 500 | 500 | 500 | 500 |

| Reference Output (KG/HOUR) | 40-100 | 100-400 | 300-600 | 500-1000 | 1000-2000 |

About factory

About factory

Certification

Certification

Customers list

Customers list  Exhibition and Worldwidely

Exhibition and Worldwidely

Product Categories : Co-kneader > SJW Serial Co-kneader

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.